CAD-based planning time calculation

Automated calculation of manufacturing costs

In order to further increase the effectiveness of the planned time determination and to reduce the effort compared to the description in the dialogue, we are working on the import of 3D CAD data. The aim is to generate the sequence of operations and automatically calculate the target times or manufacturing costs. Below you can see the current development status.

In order to further increase the effectiveness of the planned time determination and to reduce the effort compared to the description in the dialogue, we are working on the import of 3D CAD data. The aim is to generate the sequence of operations and automatically calculate the target times or manufacturing costs. Below you can see the current development status.

Generation of Material and Production Plan

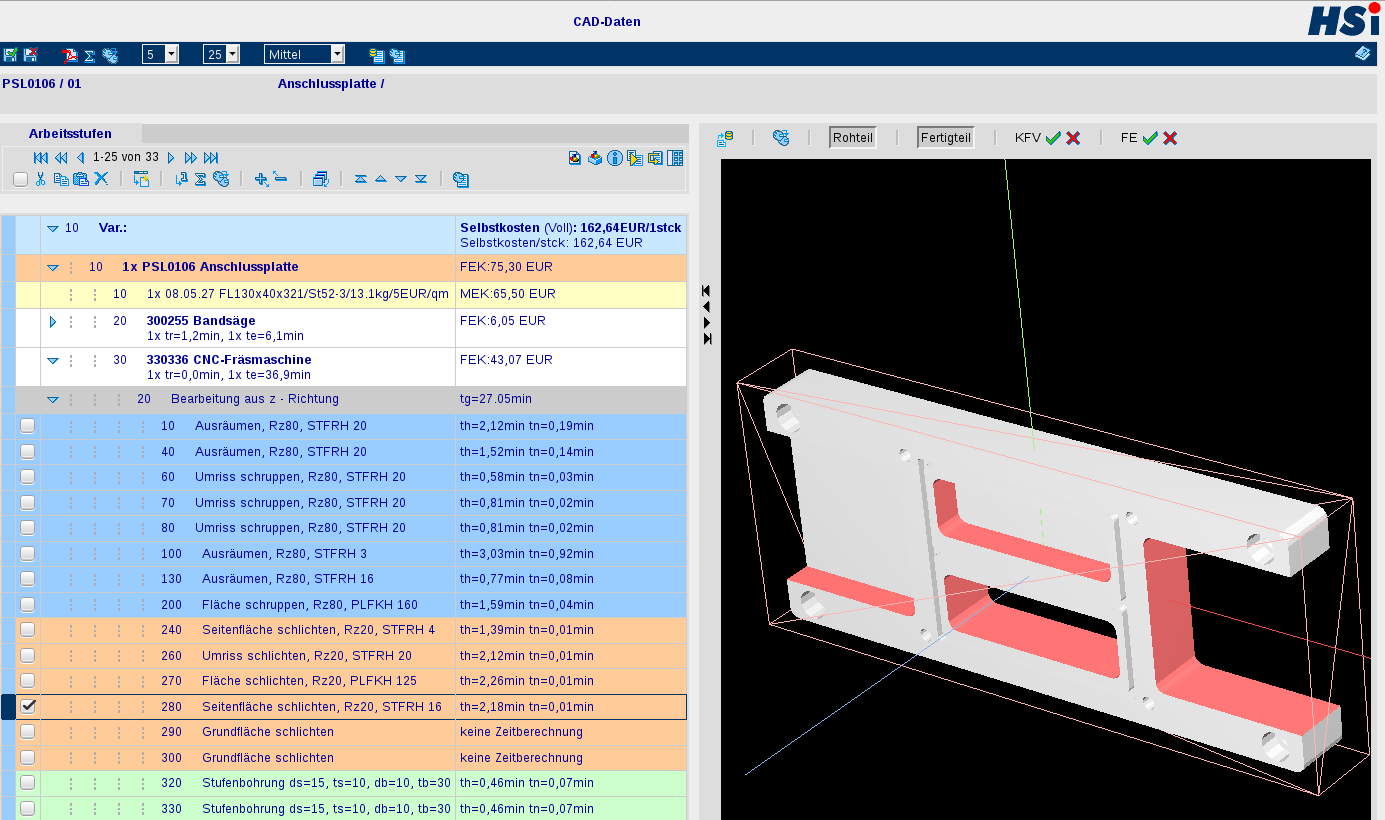

The HSi system analyses the CAD model and concludes with an oversize calculation for a suitable material article. A complete structure is generated consisting of a sequence of operations including sawing, milling, surface treatment, grinding and control.

Automatic Time Calculation

The rough-machining volume is determined by comparing the blank with the finished part. An algorithm concludes the surfaces likely to require higher-quality surface machining. The system automatically selects the necessary tools according to the machining direction, accessibility and the dimensions of volumes and surfaces. In the generated work steps, main and secondary times are calculated directly on the basis of the machining path and the cutting values stored in the technology base. The drilling and thread calculation is done by processing a feature list and assigning it to the appropriate calculation modules. A graphical representation of the data illustrates the calculated results directly in the 3D model and an interaction between model and calculation is enabled. A manual component description by entering the dimensions of the form elements is no longer necessary.

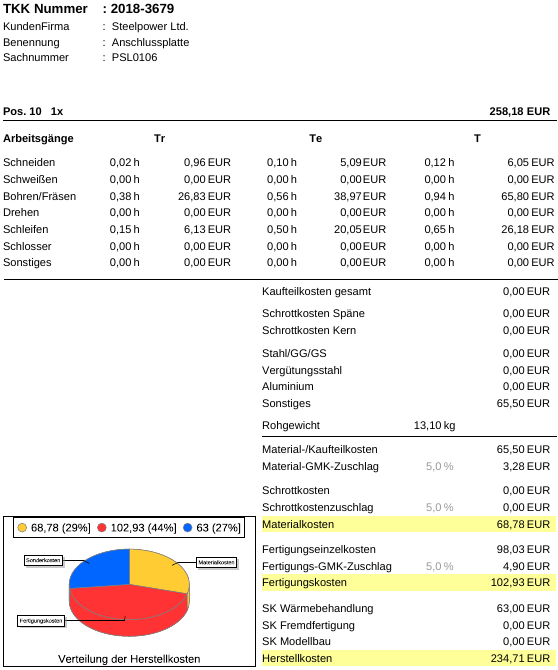

Calculation of Manufacturing Costs

Complete set-up and piece times are required to calculate the production costs. The number of tools determined is included in the setup time. The accessibility of the volumes and surfaces to be machined indicates the number of clamping set-ups that flow into the secondary time. The manufacturing costs are calculated transparently using a calculation schema that has already been defined.

Fields of Application

- • Quotation and cost price calculation

- • Engineering-related calculation

- • Comparison calculation of supplier quotations

- • Piece time calculation in work planning

Your Requirements:

- • Fast and reliable calculations based on CAD data

- • High degree of automation

- • Uniform calculation basis

- • All-in-one solution for all production processes

- • Multilingual system

Your advantages and benefits:

- • Large reduction in time required for the calculation

- • Relief of employees through automation of schematic processes

- • Reliable times due to use of the HSi technology base

- • Highly accurate and reliable calculations

- • Reduction of the subjective factor

- • Continuous use in engineering, production planning and purchasing